QC Procedures

Quality Excellence

Uncompromising Commitment to Reliability

Package Inspection

Upon receiving components, we conduct thorough inspections of the packages.

Document Verification

We meticulously verify the components by referencing them with their respective datasheets.

Digital Photography

We capture photos of all received parts and maintain a comprehensive visual record.

Label Verification

We verify the accuracy of labels on each component, ensuring alignment with the specified information.

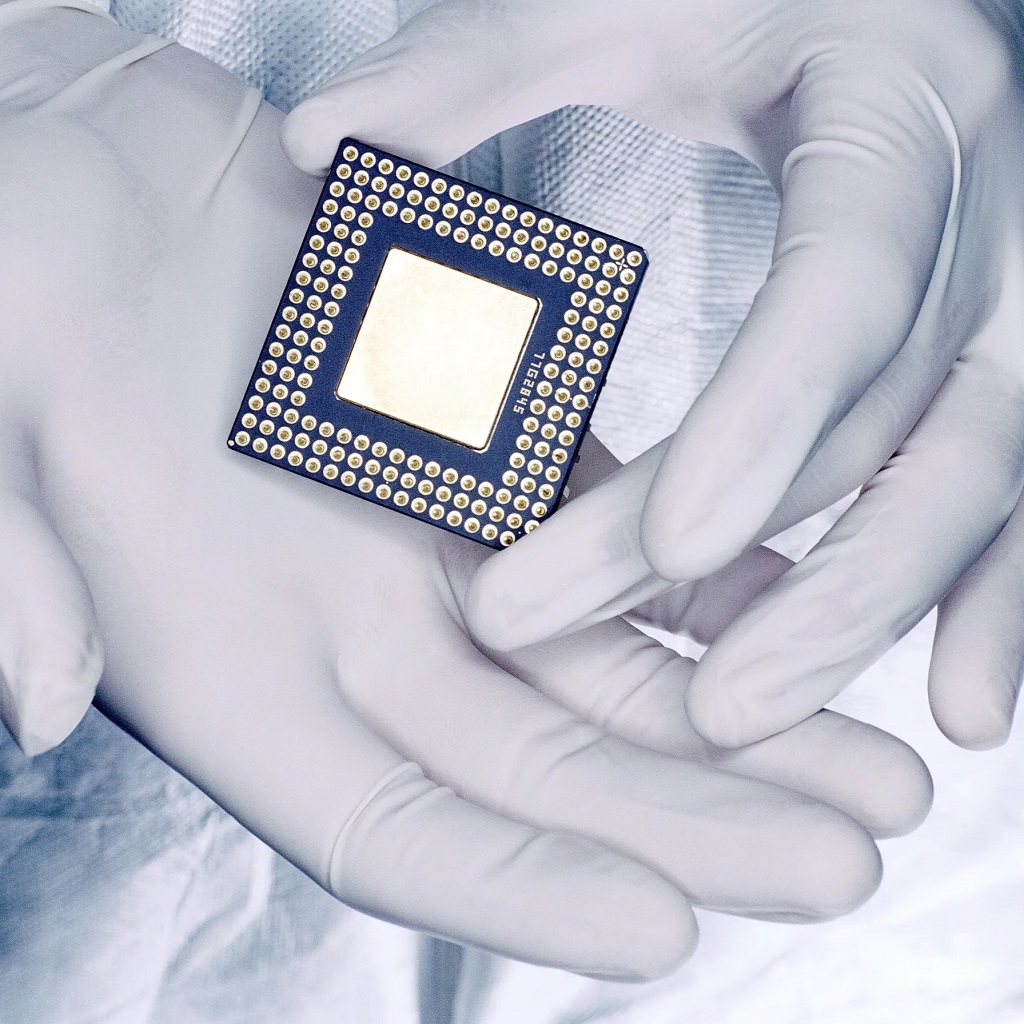

Visual Inspection

A meticulous visual inspection is performed for each component, ensuring that they meet quality standards.

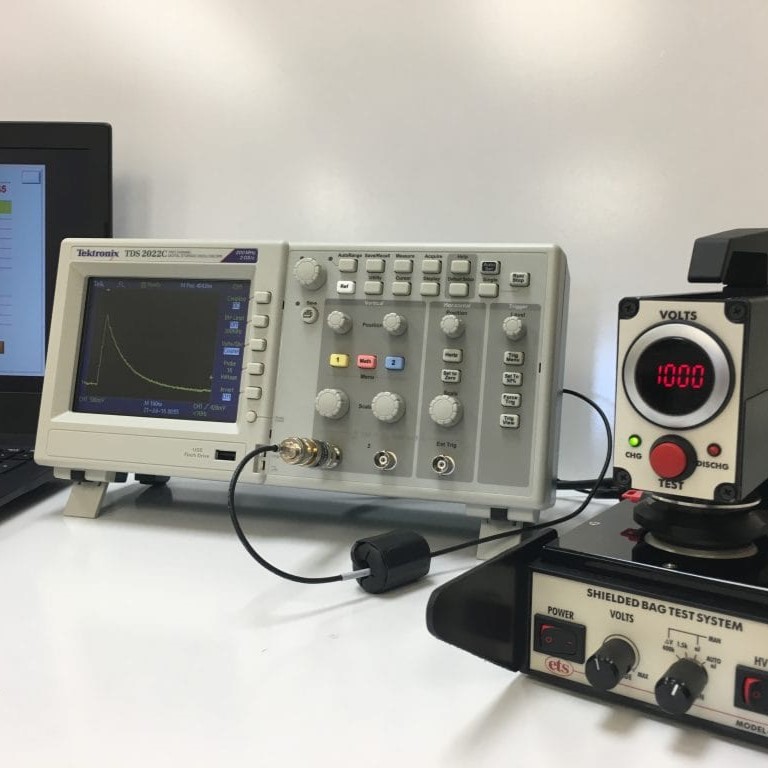

Measurement

We conduct precise measurements for all dimensions of the components.

Requirement Verification

We can undertake additional verification processes tailored to meet specific customer requirements.

Testing

We employ both physical and chemical testing methods to ensure thorough examination and quality assessment.

Documentation Management

Capturing Every Detail for Quality Assurance

Comprehensive Inspection Check

Assessing Components with Precision and Care

Labels

Outer Box / Packing

Part Top / Bottom / Side

Data Sheet

Pins / Leads / Solder Balls

Packaging

Dimensions

Discrete Value

Markings

Marking Permanency Test

Surface / Acetone Test

Scrape Test

Digital Caliper

Microscope

Automatic Counting Machine

LCR Meter

Acetone / Swab / Scraper

Digital Multimeter

Lead Check Swabs

Vacuumizer / Sealing Machine

Scanner

Electrostatic Protected Area

Dry Cabinet

Desktop Ion Fan

Precision Inspection Instruments

Advanced Tools for Accurate Evaluation

Third-Party Testing Services

Need Further Testing?

Related Pages

Explore for More Information

Application Fields

Application Fields Industries We Serve Powering Innovation Across a Range of Industries Automotive Meeting the increasing demand for technological innovation...

Read MoreThird-Party Testing

Third-Party Testing Precision Certified Elevating Confidence through Independent Evaluation of Component Performance Elevate your assurance in component quality with our...

Read MoreEnvironmental Controls

Environmental Controls Safekeeping with Care Guaranteeing Component Integrity through Certified Controls and Automated Safeguards Globally, our storage facilities strictly follow...

Read More